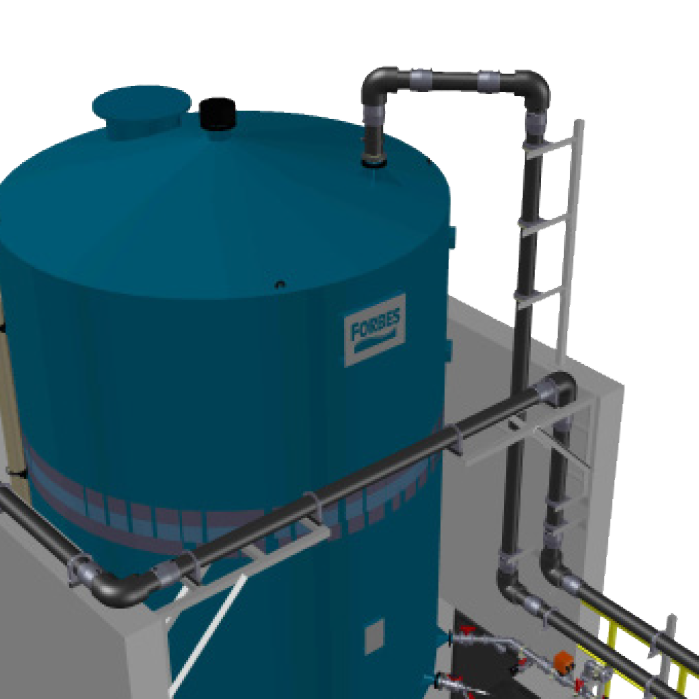

Detailed, customised, design by our experienced team of engineers, using the latest 2D and 3D software, ensures the optimal tank solution is achieved, every time. The Richard Alan team are capable of designing, manufacturing and installing a range of storage tanks, stainless steel storage tanks and double walled storage tanks, in order to suit a variety of industrial uses.

We work to the following design codes:

Storage tanks are fabricated and assembled under our ISO9001 management system by skilled and coded welders to EN ISO 9606-1 2017 and BS EN 287-1 2011, providing confidence to customers of a high-quality product. We can provide tanks in the following materials:

The Richard Alan mobile workforce will undertake the storage tank installation on-site with capability for additional fabrication of structural steelwork, process pipework, thermal insulation, electrical, instrumentation, control and commissioning.

Our design department use sophisticated modelling software to provide simple, visual solutions to complicated questions, by taking into consideration the operating conditions and calculations of the space and loads that the silos will be subjected to. All our Silos are designed to BS EN 1993-4-1.

With manufacturing capable of handling a mixing and storage capacity from 50kg hoppers to 50 tonne silos and above, plus tank packages ranging from 0.3 m³ to in excess of 100m³, manufactured to specific design codes or custom-made.

Our NEBOSH-qualified engineers are able to carry out full installations on the completed silos on-site, following all necessary health and safety protocols.

Traditional commercial cooking vessels use atmospheric cooking, which utilities a jacket. They can be used for a multitude of recipes including, but not restricted to, the manufacture of Sauces, Preserves, Condiments, Confectionery and Cosmetic products.

All our hygienic vessels are manufactured to the highest standards and ensure all welds adhere to current regulations to prevent contamination. We can also supply CIP (Clean in Place) spray balls for a quick and efficient method of cleaning your vessel after or between use.

A range of options are available including load cells, level & temperature probes, pressure gauges, sight glass, safety grills, man-ways, inline mixers, pumps, heat exchangers & dosing systems.

Want to know more about what we offer? Got a specific project you’d like to discuss? Then we’d really like to hear from you! Call us on:

+44 (0)1924 467040

or send us an email request.